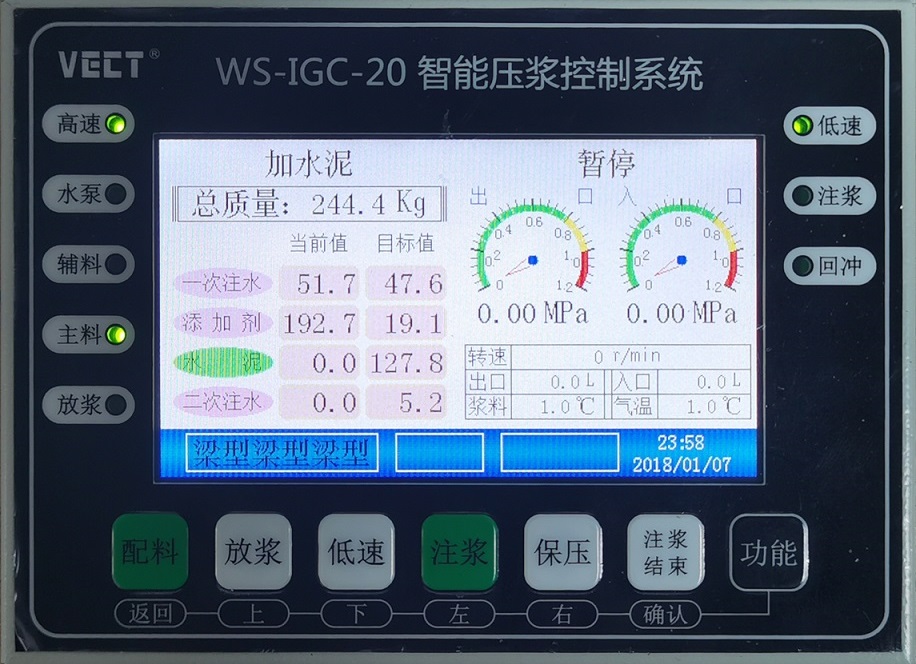

WS-IGC-20 Prestressed Grouting Controller

The combination of this system and the trolley can realise the integration of automatic feeding, automatic measuring and automatic data recording, which is fully functional, reliable and durable. Data platform management, can be docked to most third-party platforms.

Model Number: WS-IGC-20

Brand: VECT Xi'an Wanshuo Electronic

Type: Prestressing Intelligent Grouting Control System

Product Features: Intelligent Grouting, Platform Management, Data Download, 4G Module

WS-IGC-20 is a prestressed intelligent grouting control system developed by Xi’an Wanshuo. It has the characteristics of fully automatic, complete function, reliable and durable.

Product Introduction

WS-IGC-20 prestressed intelligent grouting control system is a special grouting control system designed for bridge construction. The system is divided into two process control links: pulping and grouting, the two can be operated independently. The pulping process automatically controls the start-stop of each motor by collecting the slurry quality returned by the load cell to control the ratio and mixing time, realize the intelligence and automation of the pulping process. The grouting process controls the speed and start-stop of the grouting pump by collecting the inlet, outlet pressure and inlet flow and outlet flow, keep the grouting pressure constant, and it can be automatically pressurized according to a preset time, fully automated control of the grouting process. The system has the characteristics of high degree of automation, accurate measurement, simple operation, reliability and durability, widely used in highway and railway construction projects.

Product Features

- 3 jacks independent dynamic weighing patented technology, weighing signal all-digital transmission, accuracy can reach 0.1Kg;

- Support 2 jacks pressure and 2 jacks flow monitoring, suitable for large-cycle grouting, vacuum grouting and other different needs;

- Support 6 motor control and 1 channel inverter control, suitable for constant pressure grouting;

- Using 5-inch TFT LCD screen, the picture is clear and concise and easy to operate;

- 7 physical buttons, support 16 external buttons, can be installed by function buttons;

- The signal processing section is designed with precision, low-drift devices to ensure signal acquisition accuracy;

- Multiple interface protection, ESD electrostatic protection, output current limiting, short circuit protection, input overvoltage, overcurrent protection, perfect protection can make the equipment even in the signal line short circuit and other situations to ensure that no failure occurs, reduce maintenance and after-sales costs;

- Independent wiring harness, quick to plug and unplug, easy to exchange accessories to troubleshoot, quick maintenance;

- Dedicated hardware design, compared with general-purpose platforms such as general-purpose PCs or PLCs, is more conducive to cost allocation, and the product reliability is higher under the same production cost;

- Critical devices are designed for increased redundancy to extend the mean time between failures;

- The software is based on RTOS real-time operating system operation, compared with the non-real-time operating system of similar products, the time control is accurate and timely, which is conducive to control accuracy, while cutting useless functions to ensure that the system is streamlined and reliable;

- Adaptive batching and grouting control algorithm, part of the control parameters can be adjusted on site, easy to calibrate, widely adapt to a variety of different structures and different working conditions;

- Easy operation logic and support for automatic/manual switching to handle a wide range of situations;

- Accurate recording of grouting and batching data with tamper-proof functionality;

- Through the 4G network, data can be viewed and downloaded remotely at any time, and third-party platforms can be connected;

Basic Parameters

| Dimensions | 425*200mm |

| Cut-out size | 395*175mm |

| Display size | 127mm |

| Weigh the interface | Transmitter input:3; Transmitter to host digital interface |

| Pressure interface | 2; 4-20mA Analog current interface |

| Traffic interface | 1 |

| Control the output | 7; 24V/1A Drive capability |

| Frequency conversion interface | 1 voltage speed regulation+1 start signal |

| Temperature interface | 2;NTC |

| Supply voltage | 24V |

| power | ≤8W |