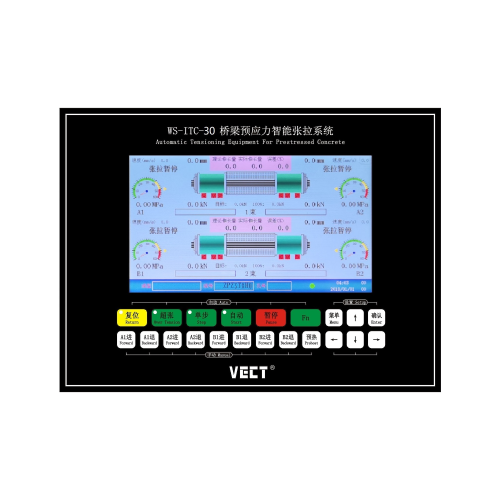

WS-ITC-30 is a general prestressed tension control system for the bridge prestressed built by Wanshuo, which is the fourth generation product and is the most widely used control system at present. WS-ITC-26 can adapt to a variety of hydraulic pumps, solenoid valves, sensors, and meet the technical requirements of most construction projects. It is easy to operate. The technical and operators can master the operation skills in a very short time. It has a unique modular design, simple connection and convenient replacement. On site problems can be quickly detected and repaired through component exchange.

Function introduction

- Each controller can control 1 or 2 jacks , supports single beam single end, double beams single end mode.

- Two controllers can be networked and can control 1 to 4 jacks, supports single beam single end, double beams single end, three beams single end, four beams single end, single beam single end, double beams single end, and pretension push mode.

- When multiple beams are tensioned, the tension force between each beam can be kept synchronous

- When two ends are tensioned, the displacement of the them can be kept synchronous

- Each jack supports forward, backward and unloading control

- Supports frequency converter control to further improve the tension force control accuracy

- Support full automatic mode, single step mode and manual mode

- Support fingerprint identification, hierarchical management, technicians and operators to set different permissions

- Printer is supported, and the tensioning results can be printed in place

- 200-2000 pieces tensioning process and tensioning result can be saved according to different contents

- Tension data can be exported through USB disk, and converted to specified format table on PC

- Tension data can be automatically uploaded to the database through 4G network and viewed through the web or app.

Unique features of the product

- Each controller can be used independently or can be networked as a host or a slave

- Spread spectrum communication technology and private transmission protocol can ensure Anti interference capability.There is low communication delay between master and slave.It has a long communication distance.The performance is not degrad due to temperature change or device aging

- Compared with the analog signal, the digital signal is not easy to be interfered to achieve high precision. The accuracy of 0.1mm can be obtained.

- The software runs based on RTOS real-time operating system. Compared with similar products based on windows, Linux or even Android, RTOS has accurate delay and timely response, which is conducive to ensuring control accuracy and is more suitable for real-time control

- The hardware and software platform are customized and developed according to the requirements. The software and hardware platform are closely combined to simplify useless functions and ensure the system is simple and reliable

- Independent hardware coprocessor. In case the main processor fails, the coprocessor cuts off the output within 1.5S

- The signal processing is designed with high precision and low drift components to ensure the accuracy of signal acquisition

- It is ergonomic to operate the whole entity key by tapping the key. The key is raised, compared with the operation of PC keyboard, mouse or touch screen, the entity function key makes the human-computer interaction closer, the operation faster, and the risk of accidental touch is very low

- There is multiple interface protection, ESD static protection, output current limitation, short circuit protection, input over-voltage and over-current protection. The perfect protection can make the equipment keep failure free as much as possible, so as to reduce maintenance and after-sales costs

- Through independent wiring harness design and quick plug and pull operation, customers can easily exchange accessories on site for troubleshooting.

- Compared with general PC or PLC platforms, customized hardware is more conducive to allocate the cost to the tension related parts, so as to ensure the reliability of the product under the premise of maintaining high cost performance. Key components increase the redundancy design to extend the mean no-fault time

- IOS-9001 quality management system Production

Applications

Classic cases

E763 road project in Serbia,the domestic team is in the charge of the intelligent prestressed tension . At first, the technicians were very worried about the impact of technical support and maintenance on the construction period or the high cost. After repeated communication, the project purchased a tensioning equipment installed with ws-itc-26 control system and some spare parts.We arranged training for relevant personnel. After the whole construction period, the customer thought that the equipment had reliable performance, easy maintenance. By remote communication with our technical support engineer ,they can do troubleshooting by theirselves, without any delay in construction progress caused of transnational factors.

Hubei section of Zhengzhou Wanzhou high speed railway

After the partner sold the equipment to the project, the customer proposed to customize some software functions for the special needs of the high-speed railway project. After evaluation, we organized the R & D team to complete the customized software according to the customer’s requirements, and quickly completed the test, providing the customer with a software upgrade package. The customer was satisfied with the use of the equipment and software, and purchased more sets of equipment in succession.

Zhengzhou Fourth Ring Road Project

As a key project of Zhengzhou City, It is pressed for time of the construction period of the Fourth Ring Road. Not only a lot of equipment is urgently needed, but also equipment debugging and relevant personnel training need to be completed in a very short time. In the face of challenges, we have made plans with many partners, fully invested in the service of the project, launched more than 70 sets of equipment, organized technical support and after-sales personnel ,completed debugging, trained more than 100 technical and operation personnel for the project, and helped the customer successfully complete the project construction.

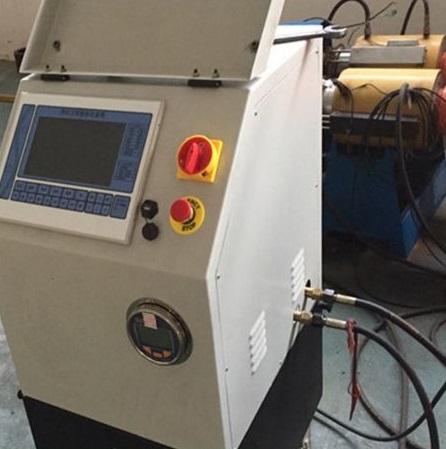

Some intelligent prestressed tension equipment adopting WS-ITC-26 system control system